ZN Process

Transform soft zinc alloy parts into wear-resistant materials with our ZN Process.

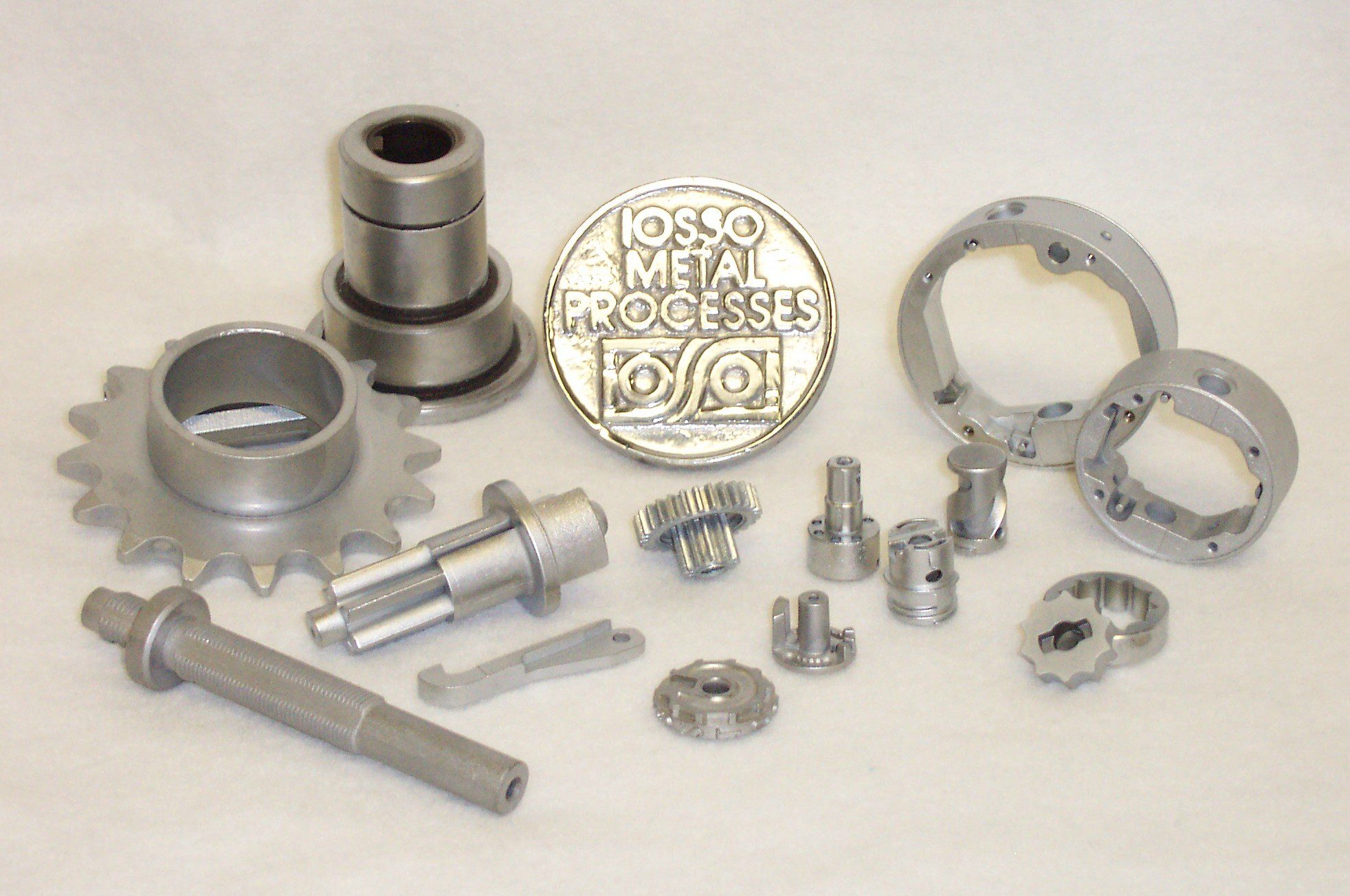

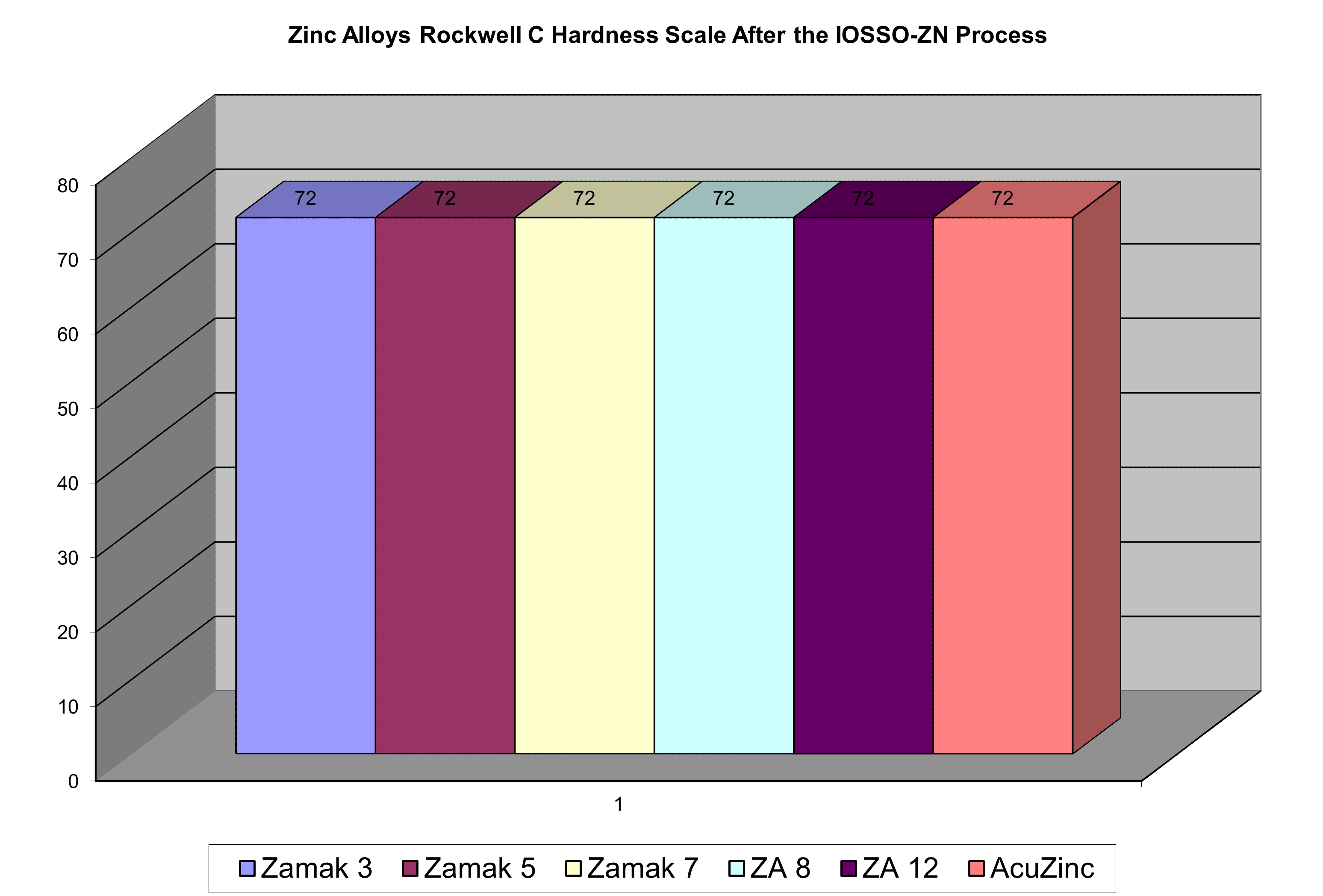

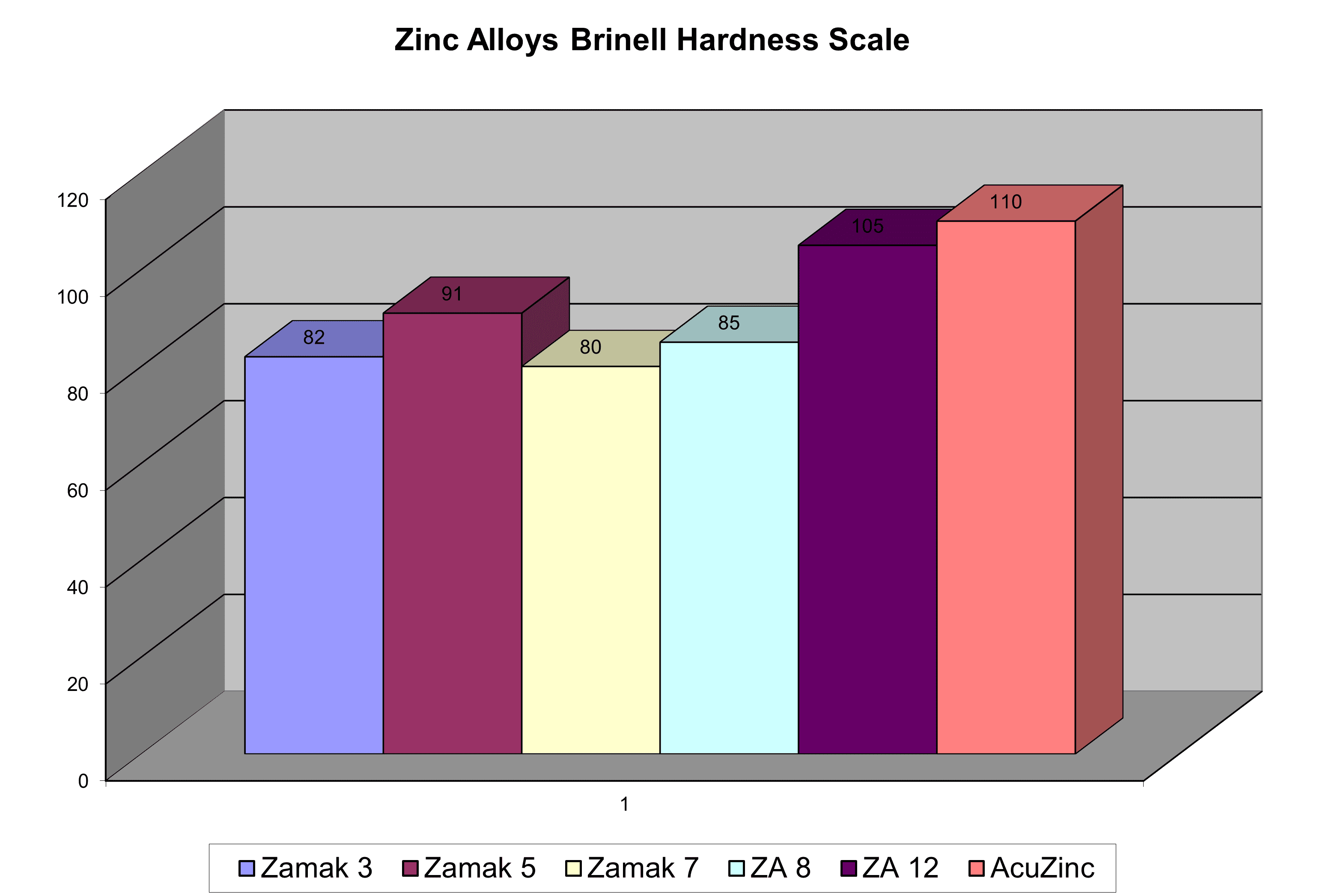

The IOSSO-ZN Process specifically transforms every-day soft zinc alloy parts into hard, extremely wear resistant materials. The patented process bonds directly with the zinc alloy surface to provide a hard outer case not simply a surface deposited coating. A new diffused surface is the result which is extremely hard and tough. Designers can now incorporate the die cast technology with the IOSSO-ZN Process to produce economical components with excellent strength and precise, close tolerances.

Zinc diecasting is probably the fastest, most convenient one-step manufacturing process to produce complicated metal parts. Precision close tolerance casting eliminates most machining operations. Instead of using expensive brass, iron and specialty steel castings or forgings, the IOSSO-ZN processes put conventional zinc die castings into contention to replace many of these expensive previously used alloys.

Benefits:

- Widely diversifies metals usage

- Increases surface hardness

- Extends base metal life

- Reduces corrosion

- Increases life expectancy

- Increases resistance to wear

- Reduces friction

- Increases lubricity

Characteristics:

- No peeling, flaking or spalling

- Anti-galling, anti-soldering

- Non-magnetic, static free

- Heat resistant

- Corrosion resistant

- Low coefficient of friction to

- Reduce heat and wear

Surface Thickness and Coverage:

- Controlled tolerances range from .000050 to .0005 of an inch

- Uniform over complex shapes

- No build-up on sharp edges or corners

- Color controlled from transparent to silver-white

- Process will replicate original surface finish

Applications Include by Are Not Limited to:

- Component wear parts, gears, shafts, pinions, lock parts, etc.