IOSSO-FE Process

Welcome to the Iosso-FE Process, the unique functional chrome plating process that started it all for us. Our process can be applied directly to any iron-based metal, hence the “FE” designation.

The Iosso-FE process increases the hardness of the surface up to 72 R.C. and significantly increases the base metal life expectancy. The FE process provides smooth and consistent results, free from hydrogen faults, cracks, or blisters. You should also not expect any peeling, flaking, or spalling with our process. We provide one of the safest and most durable plating processes in the market, which is Rohs compliant and TCHP compliant.

Get in touch with us today and let’s build a future together that is brighter, more efficient, and more cost-effective for you and your business.

IOSSO-FE Process Benefits:

- Increases surface hardness up to 72 R.C.

- Extends base metal life

- Reduces corrosion

- Increases life expectancy

- Increases resistance to wear

- Reduces friction

- Increases lubricity

- Economical

- Increases production by reducing down-time

- Rohs compliant

- TCHP compliant

Characteristics of the IOSSO-FE Process:

- No hydrogen faults, cracks or blisters

- No peeling, flaking or spalling

- Anti-galling, anti-soldering

- Non-magnetic, static free

- Heat resistant

- Corrosion resistant

- Reduces maintenance downtime for clean-up of mold base plates and components

Application for the IOSSO-FE Process Include but Are Not Limited to:

- Component wear parts: shafts, gears, cams, rollers, pinions, valves, valve spools, pistons, bearings, seals.

- Molds, dies, cavities, cores, ejector pins.

- Blades, knives, cutters, scissors, slitters,

- Roll forming dies, cutting tools.

IOSSO-FE Surface Thickness and Coverage:

- Controlled tolerances range from .000020 to .0005

- Penetration of base metal up to 15 millionths of an inch

- Hardness up to 72 R.C.

- Uniform over complex shapes

- No build-up on sharp edges or corners

IOSSO-FE Process Part Physical Capabilities:

- Small parts from 1/4″ and up.

- Large parts from 6 feet by 2 feet.

- Parts up to 1000# or so, also depending upon size.

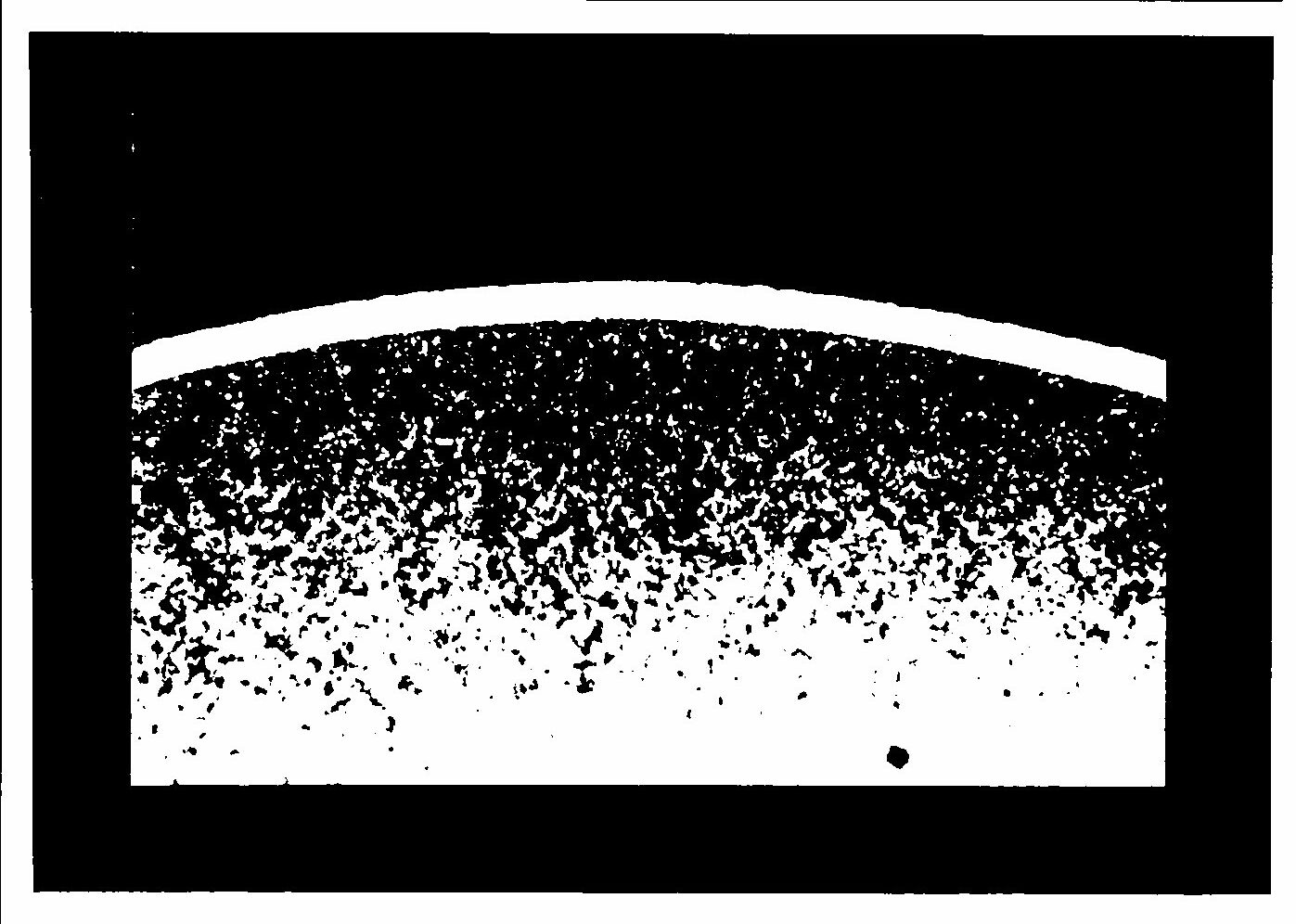

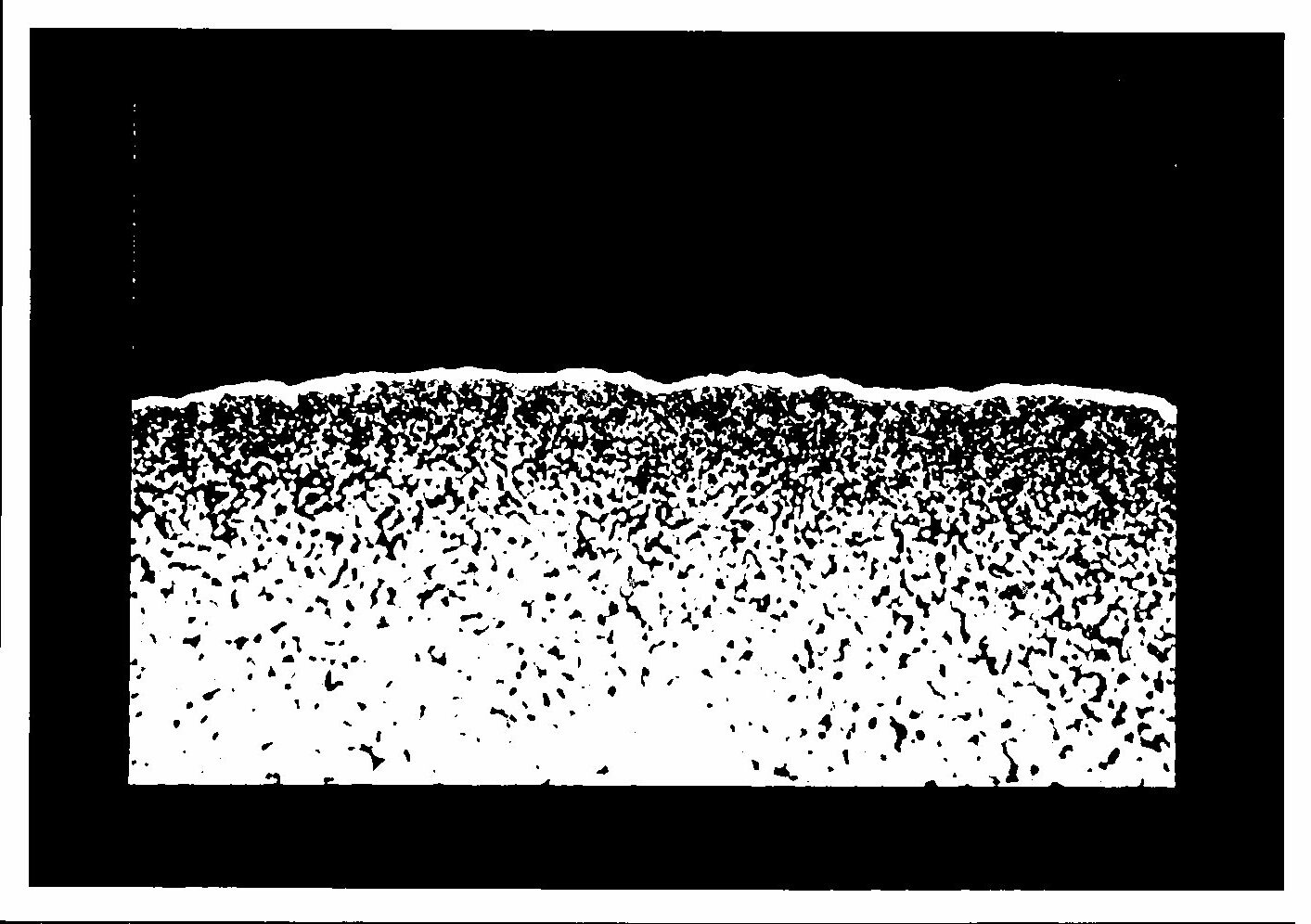

Photo Micro-graphs of the IOSSO-FE Process:

The photo micro-graphs depict contour penetration into the base metal, as well as the pore-free, crack-free deposit.

Life expectancy is 5 to 8 times greater than an unprocessed identical tool and metal plating increases surface hardness for iron based metals.